CNC Laser Cutting of Steel Sheets

Share

Brand

Viet Son Mechanical

ODM/OEM

custom

Minimum Order Quantity (MOQ)

1,000 m

Provide samples

No.

Product Condition

100% New

Main Export Market

Vietnam, Japan, Australia

Packaging

Packaging type

meter

Packaging Detail

Box

Packaging dimensions (length x width x height)

60 cm x 60 cm x 60 cm

Packing weight

50 kg

B2B Sales Policy

Road transport

Detailed description

CNC laser cutting, metal laser cutting, is one of the modern machining methods widely used in the mechanical industry. Viet Son is a professional mechanical company applying the latest technology, including CNC laser cutting, to meet the increasing demands of the market and customers.

What is metal laser cutting?

Metal laser cutting is a modern mechanical processing technology

Metal laser cutting is a mechanical processing method that uses laser technology to cut metal materials such as steel, aluminum, copper, stainless steel, titanium, and many other types of metals.

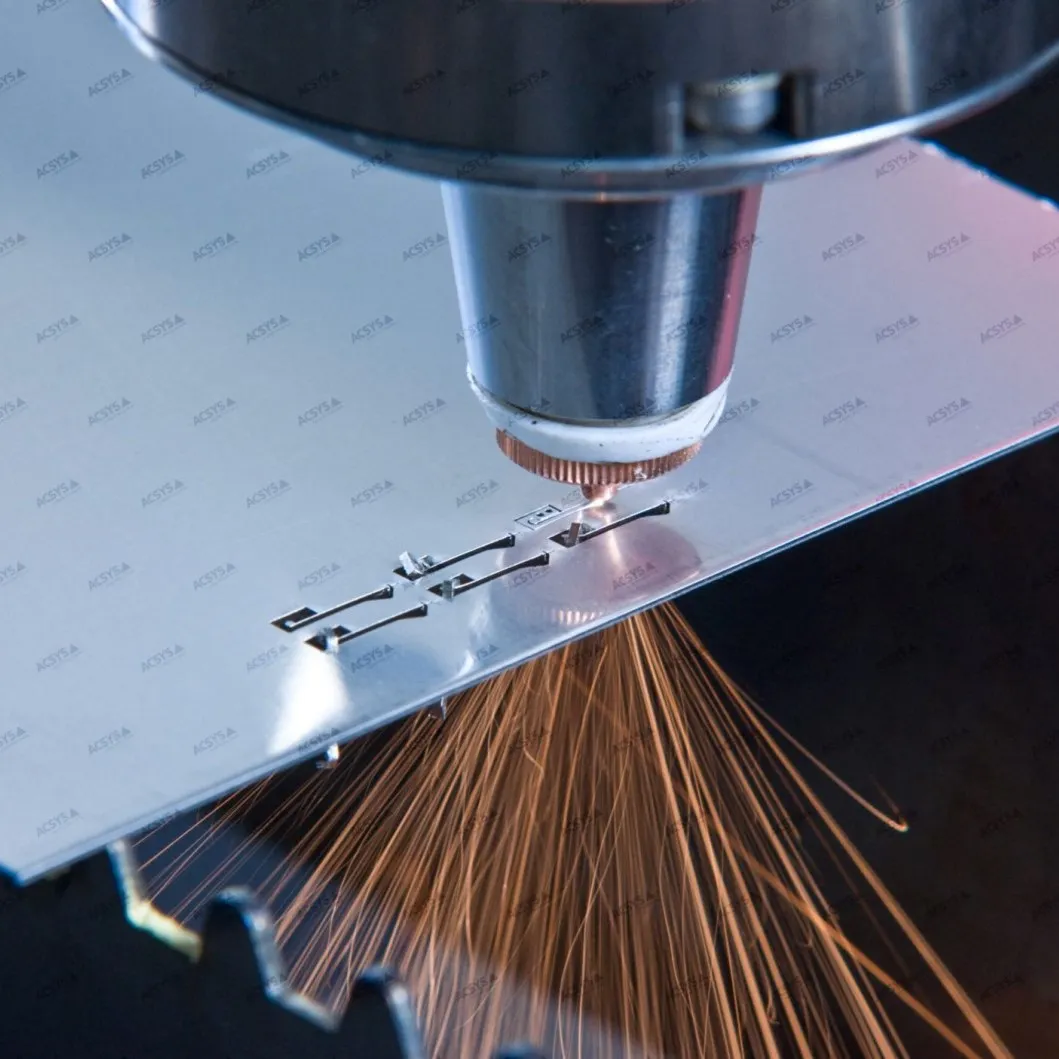

During cutting, the laser beam is focused to create a very hot spot on the metal surface, causing the metal to burn or evaporate at that point. This makes processing more accurate and efficient than traditional methods.

Metal laser cutting is often used in mechanical products such as industrial machinery, automotive components, household appliance manufacturing, and many other applications.

Advantages of metal laser cutting over traditional methods

Metal laser cutting has many superior advantages over traditional cutting methods such as wire cutting, plasma cutting, and oxy-fuel cutting.

High flexibility: During the process, there is no need to change cutting tools, even when cutting many systems of holes and other complex shapes.

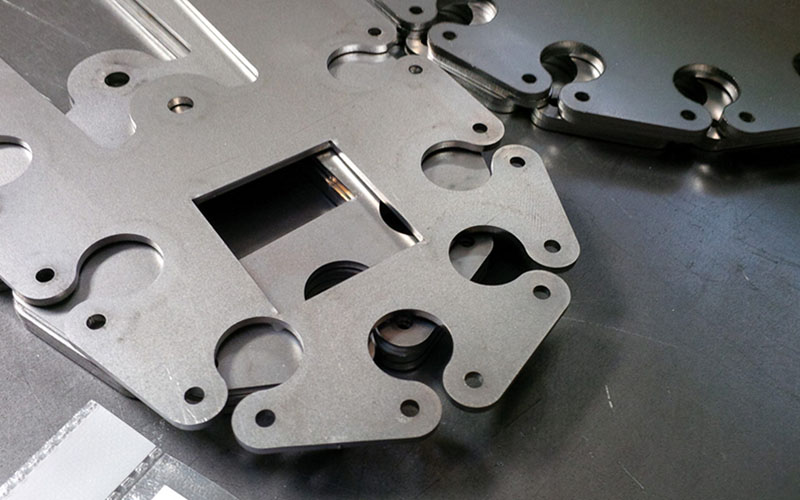

High accuracy: Accuracy of +/- 0.15 mm ensures high quality, meeting all customer requirements.

Repeatability: Ensures the processing of a series of parts on a metal sheet with the same parameters.

Speed: Laser cutting machines are known for their fast working speed, especially when cutting thin metal sheets.

Cost savings: CNC laser cutting machines are improved to save costs, with worktables applying many modern technologies, reducing the need for loading and unloading, which means reducing manual labor. Lower production costs lead to the best product value for customers.

Time saving: Automated laser cutting due to machine programming from drawings, saving considerable time for businesses and speeding up production progress.

Small heat affected zone: With a small cut, the laser cutting machine retains heat better, reducing product deformation compared to other cutting methods.

Operating principle of laser metal cutting

Metal laser cutting relies on focusing the laser energy onto one point

Operating principle

The laser beam is emitted from a high-energy source, with a high temperature. The converging lens system helps the laser beam focus and shine on the surface of the metal workpiece being processed.

The converging laser beam will burn and heat the metal workpiece at the position to be cut. Then, a high-pressure gas stream is used to blow the molten metal out of the workpiece, creating a smooth and beautiful cut as required.

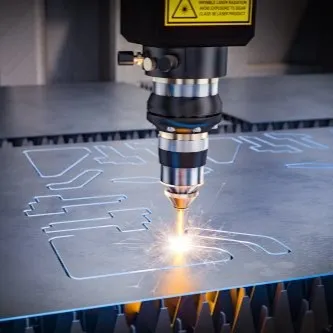

Laser cutting machines are usually programmed in advance, and when operating, the cut will follow the drawing that has been programmed by the machine beforehand. This creates patterns and shapes on the metal surface accurately, meticulously, and professionally on many types of materials such as steel, stainless steel, aluminum, copper, etc.

Metal laser cutting process

Metal laser cutting is usually performed using a CNC (Computer Numerical Control) laser cutting machine, in which the laser beam is controlled by computer software, ensuring the accuracy and consistency of the cut product.

Some influencing factors

The metal laser cutting process is affected by factors: the intensity of the laser beam, the speed of the cutting unit, and the type and thickness of the metal to be cut.

When all these factors are set accurately and appropriately to the characteristics of the metal to be cut, the cutting process will be performed quickly and accurately, creating high-quality products.

Applications, products of laser cutting, stainless steel cutting

Metal laser cutting is applied in many fields

Metal laser cutting, especially stainless steel cutting, has many applications in various fields.

Here are some examples of laser cutting and stainless steel cutting products:

Advertising products: Advertising signs, raised lettering, signage, advertising boards, light boxes...

Electronic devices: Computer parts, phone back covers, electronic components, metal shielding plates, heat dissipation plates, computer cases, phone front cover plates...

Medical devices: Metal plates for medical devices, X-ray shielding plates, hospital signage, directional signs...

Household goods: Trays, bowls, cabinets, sinks, washbasins, windows, shower windows...

Automotive equipment: Automotive parts, car windows, bracing bars, shaping plates...

Mechanical manufacturing: Machine parts, shaping plates, heat dissipation plates, door frames, stairs, railings, awnings, picture frames, tables and chairs...

Construction industry: Metal sheet laser cutting, pipe cutting is used for many products in the construction industry.

Road transport

Can't find the product you're looking for??

Share your needs with suppliers and receive direct quotes using Arobid RFQ!